Andrew L. Smith

Fort Myers, FL 33919

866-605-2480

Contact Form

Objective

To offer my experience in the development of electronic devices to individuals, inventors, corporations, and businesses of all sizes. To help build stuff: one-of-a-kind and production devices, especially those things that many people say can’t be done, but including the mundane, necessary, and important to any and all. To help other people develop and grow their businesses by making complex electronics simple and simple electronics available. To give the power of R&D to a wider customer base. To be part of a product development team.

Technical Skills |

|

|

|

Employment |

|

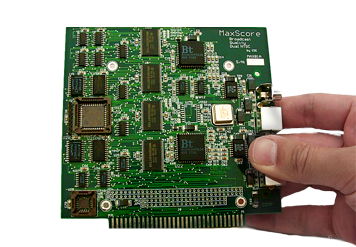

| March 1997 – Present | CSE. Ponte Vedra Beach, Florida, then moved to Fort Myers, FL Owner, Consultant Moved operations of CSE in Minnesota to a new location in Florida. Continued as principal for development of electronic hardware devices for existing customers as well as new customers from areas in and around the Florida location. Help develop product concepts through discussions with technical and non-technical clients alike. Produce devices ranging in complexity from fan drive systems and water softener controllers to PCMCIA LAN diagnostic cards.Developed effective relationships with proficient manufacturers as well as the worlds largest component distributors for volume as well as quick-turn production of products. Provide personal discussions with customers to develop specifications and design objectives. Research available solutions. Perform industry wide component and technology research for projects and devices. Generate computer readable schematics for board layout and/or VHDL. Perform internal sub-circuit testing. Generate gerber files for PCB fabrication. Design enclosures as necessary. Procure all necessary components when preferred. Assemble boards or produce highly efficient kits for assembly houses. Develop all necessary software in C or assembly. Receive assembled boards for testing and approval. Ship to customer complete for approval. Produce highly accurate and thorough documentation packages for internal reference and customer use.Most embedded processor work revolved around Microchip, Zilog, and Intel embedded processors and microcontrollers. Peripheral devices ranged from standard to invented. Power supplies range from line power to handheld low power.

|

| March 2002 – February 2005 | Safety Cast Corporation. Jacksonville, Florida Chief Scientist / Principal Engineer While sustaining CSE to support existing customers and provide guidance to new customers, operated full-time as principal developer of technologies for Safety Cast Corporation designing all hardware and writing all software and patent applications. Recommended equipment for purchase and built the electronics development laboratory for new RF product concepts. Developed a Multi-Carrier AM/FM Modulation technology and drafted the necessary documents for the patent (granted) of the Multi-Carrier Simultaneous Transmitter. Custom designed compact antenna systems for AM and FM broadcast bands.Built demonstration units and assisted with demonstrations at military and private locations. Drafted proposals and generated white papers and technical support. Designed and built multiple low-distortion interstage and output stage RF amplifiers, filters, and subsystems for various application formats in the AM and FM broadcast bands. Designed enclosure with custom heat distribution components for the best heat dissipation in the smallest form-factors. Coordinated with craftsmen for construction of custom metal components. Coordinated with customers and field tested product.Trained personnel in various technical tasks and produced assorted documentation.

|

| July 1996 – March 1997 | Concept Solutions & Engineering (CSE). Rochester, Minnesota Owner, Consultant Initiated a consultancy and offered design and manufacturing services to various start-ups as well as mature corporations, such as Amtrack, Bayer, and a subsidiary of 3M. Worked primarily with Intel and Zilog processors at the time, as well as Ethernet and Thinnet networks, 10Base-T, and PSTN (Public Switched Telephone Network) aka POTS (plain old telephone service) devices and circuits. Also began work in RF, especially 300W custom electronic designs and high speed digital circuits. Specialized in custom video solutions for industrial use. Expanded the business by hiring personnel.

|

| January 1985- July 1996 | MJS Designs. Phoenix, Arizona Senior Design Engineer Was responsible for the expansion and growthof a two person board layout company into a full manufacturing and engineering services company. While still in high school, joined what was then a two person circuit board layout company as a CAE/CAD Designer, capturing schematic “blue prints” into the computer using CAE/CAD software and reporting “human error” to our engineer clients. Worked through the ranks to operate the board layout software and designed multi-layer circuit boards. Before graduating from the local university, I had already expanded the company by offering board assembly and parts procurement services. I was then the principal trainer for manufacturing and parts procurement, operating surface mount and pin-through manufacturing equipment as well as designing processes such as for encapsulation.Wrote software for internal use, especially to provide CAD operators reports of inconsistencies between layouts and schematics, as well as the automatic generation of recommended change procedures.After graduating from Arizona State University with a BSEE, expanded the company further by offering engineering design services of electronic devices to clients. Was the principal client contact as well as design engineer. The company further expanded when my department employed other engineers and technicians under my management.

|

Education

Arizona State University

Bachelor of Science in Electrical Engineering. 1990

-

- Digital, analog, and RF systems and circuits.

- Computer and embedded processor systems.

- Intel Assembly and C.

- Electromagnetics and Quantum mechanics for semiconductor theory.

Awarded Patents

System and method for using AC and DC Sensors for Water Treatment

Awarded August 3, 2021 – U.S. Patent #11,078,091 B2

System and method for using AC and DC Sensors for Water Treatment

Awarded May 23, 2019 / August 8, 2021 – U.S. Patent #2019/0152803 A1

Current Regulator for Mobile Water Electrolyzer

Awarded April 29, 2014 – U.S. Patent #8,709,221

High Voltage Sensor Circuit

Awarded July 12, 2011 – U.S. Patent #7,977,933

Selective Message Broadcasting System

Awarded October, 2004 – U.S.Patent #6,804,490

Method and apparatus for measurement of length of cable having fixed impedance

Awarded August, 2004 – U.S.Patent #6,771,076

Device, method and system for facsimile transmission over a computer network

Awarded August, 2003 – U.S.Patent #6,603,569

Other Research & Development

Japanese film documentary on the origins of the digital system

Contributing researcher recreating the only known schematic of the Stibitz Model K binary adder which is on display at the Smithsonian.

Aqueous ion response to radio frequency excitation

Contributing researcher for improved water system operations

Material ionic decomposition

Contributing researcher for new materials for conduction

Dynamic magnetic field source behavior

Contributing researcher for the better understanding of electromagnetic properties

Methods and modes of MOSFET breakdown

Contributing product improvement researcher for private industry

Extra-curricular activities

Family, Theology, Piano, Taekwondo, Skiing, Circuits!