Cost and Pricing Estimates

The number one question that we hear is “Can this be done.. ” followed by a unique idea. Occassionally, the unique idea is not so unique, but usually it is. If it is not a unique idea, we try to show you this right away so that you can explore other angles or ideas… because if you are truly an idea generator, you are good for the economy and should not waste your time! If it is a unique idea, the answer is usually yes, but then we might inform you of other implications of your idea, such as cost, value, market, etc. We will always be able to show you ways to reduce cost if necessary or add features and function with little additional costs. Developing a concept is not the whole story, but it is the part of the story that CSE specializes in and can complete for you.

Here is a list of some of the other questions that we often hear, or that are important to consider:

How much does it cost to develop an idea?

Our pricing is based on the individual tasks being quoted. Just as projects can vary greatly in nature, so will their fees vary respectively. Some projects are solved during the initial “discovery” process and never even get billed! Others may take more than a few months. We charge a competitive rate per hour for electronics consulting, engineering design, or contract engineering depending on the type of work being performed. We will inform you right away of approximate costs involved, depending on your idea. We also recommend fees per milestone and “Not To Exceed” budgetary numbers for qualifying projects. Please call for us to discuss your particular project in detail.

How much time does it take to develop an idea?

Occassionally what takes time is waiting for craftsmen to complete their respective tasks or for special parts to arrive for use and/or testing. In many cases, these delays can be shortened if expedite fees are paid. It depends on what is being done, and by whom. CSE always tries to offer the lowest cost solution first with options including expedite fees or simple concept alternatives second. We will also work with your own skilled craftsmen or manufacturers if you have those preferences.

How many should we make?

This depends on the product and how it will be introduced into the market or used in your company. Sometimes one unit is enough. Sometimes five units is preferred. Occassionally one hundred units or more. For example, if you need a special computer device built to demonstrate a new display to your sales people, maybe only one unit is needed. This could be both the prototype and the final unit! If your product is intended to go to production, but you want to use your own manufacturing facility to produce them, five units to prove the functionality of the design might be enough. If you need time to ramp up your own manufacturing facility or have no intention of maintaining a manufacturing facility, you might want CSE to handle all of your manufacturing quantities for you after you approve the prototypes (usually three to five units, or so).

How large of a project is this?

Here is where you need to hire a consultant like CSE to briefly and then more thoroughly explore your project for you. We can then produce a report for you to discuss internally, or with us, for further design objectives. Chances are, we can both explain and handle all of the details, informing you of the many options usually available to handle very large developments.

Can you train us to take over manufacturing?

If you really want to, yes. We can train you to order parts, to inspect bare circuit boards before passing them on to assemblers, we can even train you to assemble boards! IF you really want to. Be careful of what you ask for. It’s not so bad to hire people outside to do these things. Certainly we will refer you to excellent manufacturers for each particular job.

How tiny can something be made?

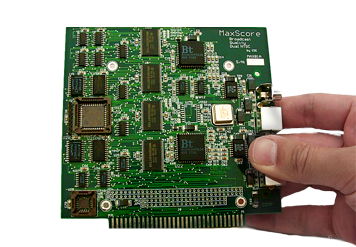

The size of a custom electronic device can be very small. Industry trends in semiconductor devices dictate the ever-shrinking sizes and lowering power consumptions. Using up-to-date, or even tomorrow’s devices, is a cornerstone of the success of CSE in new product development. This is possible with diligent research. However, should a small form-factor be a priority design goal, custom integrated circuits might be necessary. See our Links page for more information.

What is the biggest expense in product development?

The biggest expense should be in marketing the product, not developing it, because marketing should remain on-going. If it is not, then the vitals of the product may be in poor health. Sometimes, marketing can cost only time, rather than dollars. But a good marketing plan is definitely as important as the technical skills that CSE can offer you! Sometimes adding technical features to a product is mere marketing efforts in disguise. Build your prototypes, run you press releases, go to the trade shows and get them out there to build sales!

Does your company entertain shares of equity or royalties for new product ideas?

We have discussed and accepted project equity positions and royalty agreements regarding qualifying product developments in the past. Please call us to discuss your needs.